Zoem

Revolutionize Your Insect Farming with ZOEM Rack System

Embrace sustainability and efficiency in your insect farming operations with our cutting-edge ZOEM rack system. Moving beyond traditional plastic trays, the ZOEM rack offers an eco-friendly, cost-effective solution for black soldier fly farming.

It’s a modular system which is ideal for large scale farming. Another key feature is that the focus is on operational cost. We don’t move the larvae to the machinery, we move the machinery to the larvae. Which brings big advantages in efficiency and maintenance.

Why Choose ZOEM

Rack System

Over Plastic Trays?

- Sustainability First: Our racks are designed to minimize plastic usage, aligning with eco-friendly practices.

- Ease of Maintenance: The open structure of the ZOEM rack simplifies cleaning processes, ensuring optimal hygiene.

- Durability and Safety: With a lifespan exceeding 15 years, ZOEM racks are not only more durable than plastic trays but also provide a better return on investment.

- Efficiency and Scalability: Designed for large-scale operations, ZOEM racks require low maintenance, are easy to manage without specialized labor, and support a modular system for effortless feeding, mixing, and watering.

Advanced Climate Control for Optimal

Black Soldier Fly Production

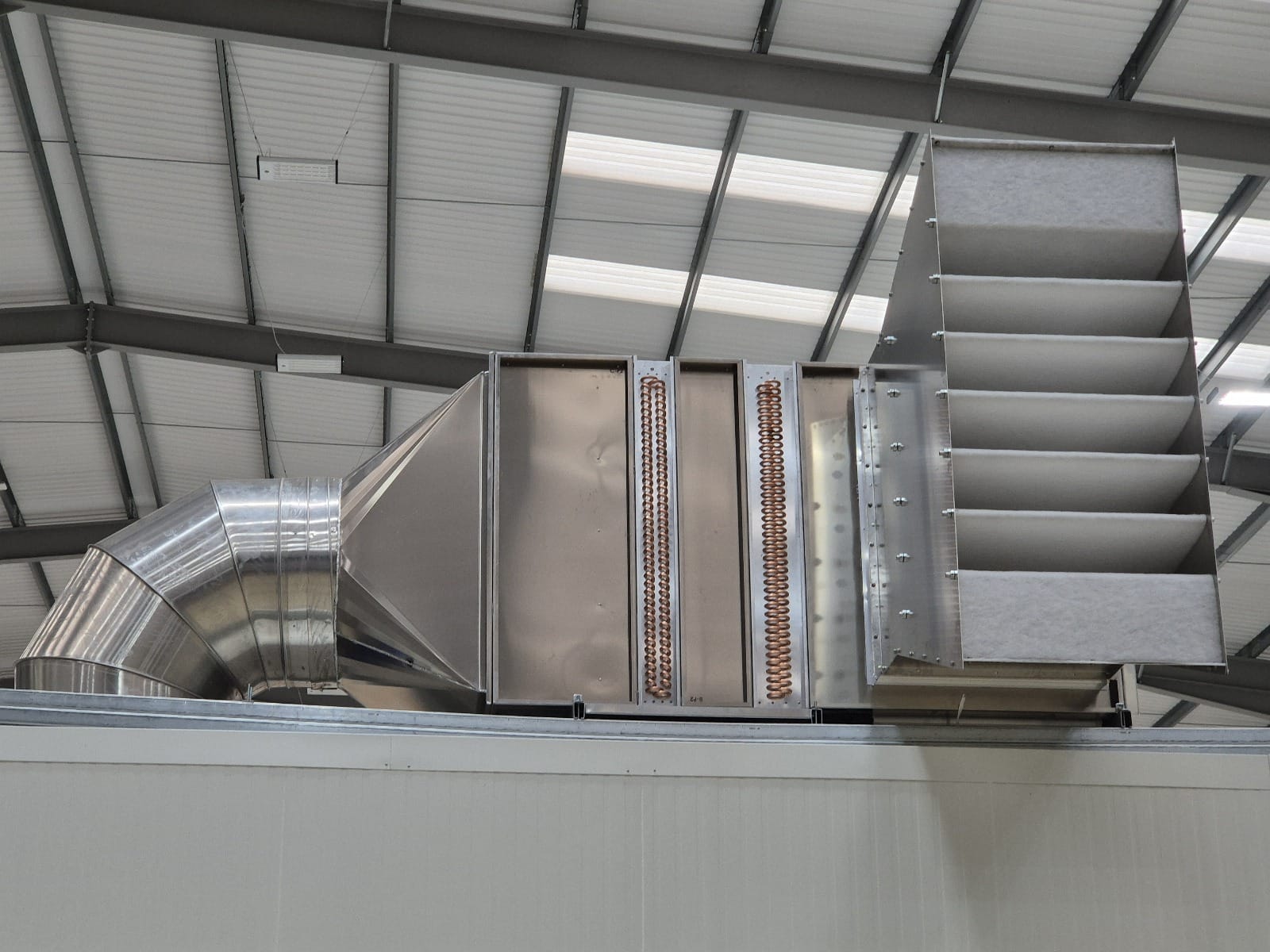

Our state-of-the-art climate control systems are tailored to the unique needs of insect farming. From prefabricated air-handling units to user-friendly climate computers, we offer complete solutions for maintaining the perfect growing conditions. Control everything from substrate temperature to humidity levels, all accessible remotely for convenience.

BSF ZOEM racks explained

• ZOEM racks require fewer personnel than trays for tasks like filling and feeding, reducing labour costs.

• ZOEM racks also have advantages in climate control. Made from aluminium, they facilitate better air circulation and temperature regulation, promoting optimal larval development.

• ZOEM racks are more adaptable with regards to substrate conditioning, refeeding and real time monitoring. Leading to a more optimal environment for the larvae.

Innovative Machinery for ZOEM Rack Management

Introducing the BSF ZOEM Filler, our solution to streamline your farming operations. By bringing machinery directly to the production rooms, we eliminate the need for transporting substrates and larvae, maintaining consistent climate conditions. The ZOEM Filler’s self-lifting construction and variable speed settings allow for precise and efficient rack filling.

Watch our system in action:

Comprehensive solutions for insect farming INFRASTRUCTURE

Our special coated BSF sandwich panels are designed with high insulation standards to promote efficient insect farming. We provide full support, from prefabricated buildings to local construction guidance, ensuring a seamless setup process.

The advantage of using these panels inside an existing building is that you don’t need a building permit as you’re not changing anything on the outside. Another practical approach from Insect Engineers.

MOST EFFICIENT HARVESTING

The ZOEM system with its flexible floors enables very fast and efficient harvesting. Only one person is involved and can probably harvest 4 times faster then a crate system. This improves working hours, processing time, operational cost and quality of product.

FLEXIBILITY IS KEY

As a grower you want to be able to make changes during the production cycle (5-14 day old larvae). The ZOEM system is unique in the market.

• Multiple feed. The ZOEM system enables adding another layer of feed during your production cycle. This can improve larvae growth and conversion rates.

• Mixing (see movie). Our ZOEM mixer can drive in the ZOEM racks and mix the layer of substrate and larvae. As often the top layer of substrate dries out because of the heat generated and air movements. The ZOEM mixer improves activity in the substrate and prevents crust forming on top.

• Automatic watering. We always thought this is not done because you will have more headaches at sieving. But it has proved that adding water can be direct and efficient way of cooling. Further it helps avoiding the top layer to dry out. In the ZOEM system you can water the entire room within 2 minutes.

On the left a movie of our ZOEM mixer in action.

EXCELLENT CLIMATE IS THE FOUNDATION

Climate control systems and well-insulated growing rooms are main aspects within your growing environment and will determine the quality conditions of your insect farming.

We have been developing prefabricated, easy-to-install and energy-efficient air-handling units, air distribution systems and user-friendly climate computers for many years now.

Air flow is critical in an operation where there is a lot of heat generation by the larvae in the substrate. This hot air needs to be transported away to maintain a proper substrate temperature. That also means that there need to be open areas to enable the air to move. It’s not possible to just load a complete room full of crates or ZOEM racks. Distances between each layer and distances inside the room are key aspects of our knowledge to maintain an optimal climate-controlled environment.

Unique for the ZOEM system is that continuously substrate temperature is measured to maintain the ideal living conditions for the BSF larvae.

SOFTWARE

We offer very complete software packages. Which will include monitoring of climate conditions, yield data and recipe asignment, But this can be expanded with real time analyses, AI implementation, staff management, stock levels, energy efficiency, cloud features, and many more.